Top Tips for Choosing the Right Switch Disconnector?

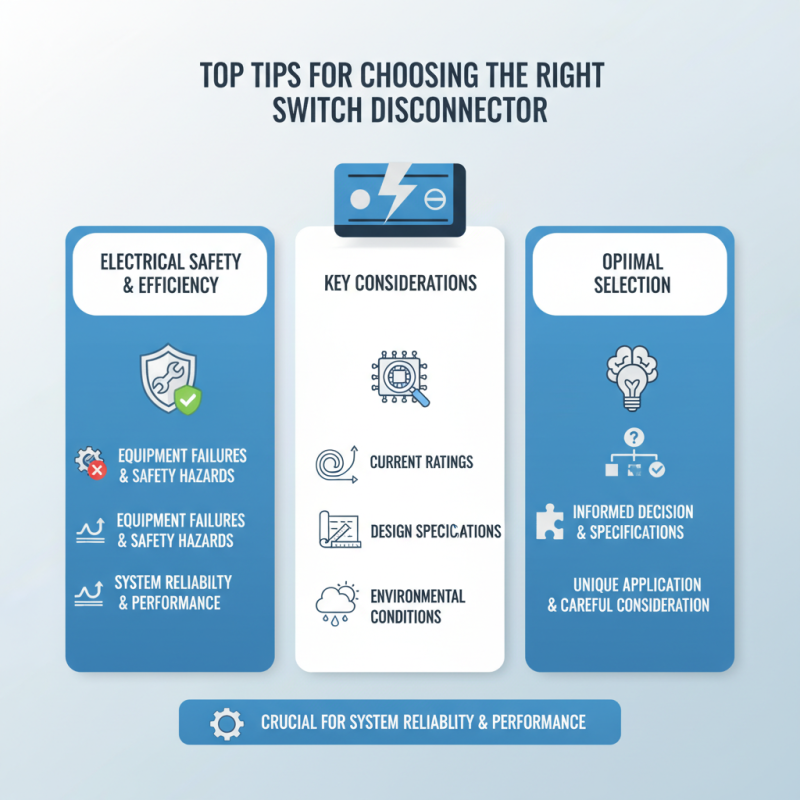

Choosing the right switch disconnector is critical for electrical safety and efficiency. According to a recent report by the International Electrotechnical Commission, improper selection can lead to equipment failures and safety hazards. Industry expert John Smith emphasizes, “Selecting the appropriate switch disconnector is vital to maintaining system reliability and performance.”

Switch disconnectors play a key role in controlling electrical circuits. They can isolate parts of a system during maintenance, preventing accidents. Yet, many professionals overlook specific criteria when making their choices. Failures can arise from factors like current ratings, design specifications, and environmental conditions. A mismatch can result in significant costs and risks.

With various options available, making an informed decision is essential. Many engineers struggle with identifying the right specifications. There's no one-size-fits-all; each application is unique and requires careful consideration. Understanding the complexities is crucial for achieving optimal outcomes in the selection of switch disconnectors.

Understanding the Purpose and Functionality of Switch Disconnectors

Switch disconnectors are crucial in electrical systems. They serve the primary purpose of isolating a circuit for maintenance. This functionality protects both personnel and equipment. According to a recent industry report, around 30% of electrical faults arise from inadequate disconnection. This highlights the importance of choosing the right disconnectors carefully.

When selecting a switch disconnector, evaluate its specifications. Consider current ratings, voltage levels, and the installation environment. For example, outdoor installations require weatherproof options. Studies indicate that improper installation can lead to a 40% increase in failure rates. Therefore, attention to detail is vital.

Moreover, the type of application impacts the choice. Specific systems might need manual operation, while others benefit from automated solutions. The functionality must align with the unique demands of the application. Ensure that the switch disconnector supports the safety standards outlined by regulatory bodies. Overlooking these details could result in costly mistakes.

Key Specifications to Consider When Selecting a Switch Disconnector

When selecting a switch disconnector, key specifications play a pivotal role. Start with the voltage rating. Ensure it matches your system. Consider the current rating next. It directly impacts the device's efficiency. A higher rating can lead to overheating if not properly matched.

Body size and mounting type are also crucial. Compact designs save space but might limit handling. Look for ease of installation. Some models require specific tools, adding complexity. Evaluate the breaking capacity as well. It's essential for safe operation during fault conditions.

Don’t forget about the operating mechanism. Manual and automatic options exist. Each has its pros and cons. Some users struggle with manual handles in tight spaces. Automatic switches might seem efficient, yet can malfunction under certain conditions. Close attention to these details can prevent costly mistakes.

Top Tips for Choosing the Right Switch Disconnector

Assessing the Environment and Application for Optimal Performance

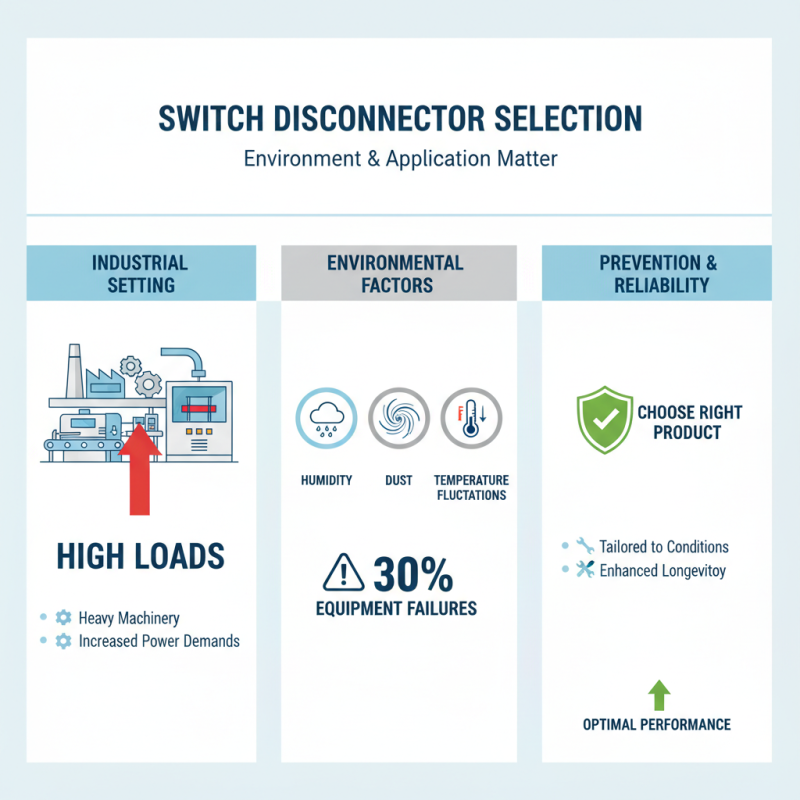

When selecting the right switch disconnector, the environment and application are critical. An industrial setting with heavy machinery requires a disconnector that can handle higher loads. Humidity, dust, and temperature fluctuations can compromise performance. Reports show that 30% of equipment failures stem from environmental factors. Choosing the right product helps prevent these issues.

It’s essential to assess the specific needs of your operation. Consider the installation location. Is it exposed to moisture or extreme temperatures? Such conditions require robust solutions. Compatibility with existing systems is another aspect to ponder. Not every model suits every situation. Misaligned systems can lead to inefficiency.

Tip: Always check the insulation ratings. A poor choice can lead to costly downtime. Ask your team for input regarding past experiences. Include their insights to avoid common pitfalls. Remember, taking time to evaluate your environment can save money in the long run. Rushed decisions may result in regrets later.

Evaluating Safety Standards and Compliance in Switch Disconnectors

When evaluating switch disconnectors, safety standards should be your top priority. According to a recent industry report, compliance with IEC 60947-3 is essential. This standard ensures reliable performance and reduces risk in electrical systems. Non-compliance can lead to system failures. These failures could pose safety risks and impact operational efficiency.

It's not just about compliance. Understanding the specific applications is crucial. For example, disconnectors used in industrial settings require higher ratings. A study highlighted that approximately 15% of failures occur due to inadequate rating selection. This data emphasizes the need for proper assessments. Users often overlook details like environmental conditions and load types. These factors can significantly influence performance and safety.

Moreover, while testing and certifications offer guidance, they should not be the only factors considered. Many users mistakenly assume that certified products guarantee full safety. However, a disconnector may pass tests yet still lack optimal design for field conditions. Recognizing this gap is vital. Prioritizing thorough evaluations can lead to better decisions and safer systems.

Top Tips for Choosing the Right Switch Disconnector

| Feature | Description | Compliance Standards | Safety Rating |

|---|---|---|---|

| Current Rating | Maximum load current the switch can handle. | IEC 60947-3 | IP55 |

| Voltage Rating | Nominal voltage the switch can operate at. | IEC 60947-1 | Class II |

| Insulation Resistance | Resistance value to prevent short circuits. | IEC 60255-27 | 500MΩ |

| Breaking Capacity | Maximum fault current the switch can interrupt. | IEC 60947-3 | 15kA |

| Durability | Number of operations before failure. | IEC 60947-3 | 10,000 Operations |

Comparing Different Brands and Models for Best Value and Reliability

When choosing the right switch disconnector, it's essential to compare various brands and models for the best value. Each brand may offer unique features. Some models prioritize efficiency, while others focus on durability. Consider what features matter most for your application.

One valuable tip is to check the specifications. Look for the rated current and voltage levels. These figures impact the device's performance under load. A higher rating could mean better reliability. However, be mindful of the product's size and integration into your system.

Another aspect to reflect on is the reputation of the brand. User reviews can provide insights. While ratings help, they are not always perfect. Take time to read what others have said. Keep an eye out for common complaints across models. This can highlight potential weaknesses in performance or reliability.

Related Posts

-

Exploring Market Trends for Switch Disconnectors at the 138th Canton Fair 2025 in China

-

7 Facts You Didn't Know About ACB Breakers: The Best Choices for Your Electrical Needs

-

7 Essential Tips for Choosing the Right Air Circuit Breaker for Your Electrical Systems

-

2025 Top Switch Disconnector Trends and Key Features You Need to Know

-

How to Choose the Right Electric Breaker for Optimal Safety and Efficiency

-

10 Essential Tips for Choosing the Right Miniature Circuit Breaker for Your Projects