How to Choose the Right Motor Protection for Your Equipment?

Choosing the right motor protection for your equipment is crucial. These devices ensure that your motors function safely and reliably. When selecting the right protection, consider several factors. Not all environments are the same. Unique operating conditions require specific protection features.

Motor protection can prevent damage from overloads, short circuits, and overheating. It is essential to review the specifications of your motors and compare them to available protection options. Some devices have advanced features, while others are basic. Ask yourself if your environment is harsh. If so, a simpler model may not suffice.

Integrating the correct motor protection enhances the longevity of your equipment. However, many overlook this aspect during selection. Take time to research before making decisions. The right choice can reduce potential risks and costs. Reflect on the specific needs of your operations. Motor protection is not just an accessory; it is a critical element for performance and safety.

Choosing the Right Motor Protection Based on Operating Environment Requirements

Choosing the right motor protection involves understanding your operating environment. Factors like temperature, dust, and humidity can impact motor performance. For instance, motors used in humid conditions need special coatings to prevent moisture damage. In dusty environments, dust filters are essential to maintain airflow and cooling.

Reflect on your equipment's location. Is it in an industrial setting, or perhaps a more exposed area? Adjust your choice based on these details. An outdoor environment may require enclosures that are weather-resistant. However, these solutions can be more expensive, and you might not have the budget.

Take note of potential oversights. Some may neglect vibration levels or the presence of corrosive materials. This can lead to premature failure of motor protection systems. Ensuring proper specifications can make a significant difference in equipment longevity. Do not rush this process; thorough assessment is key.

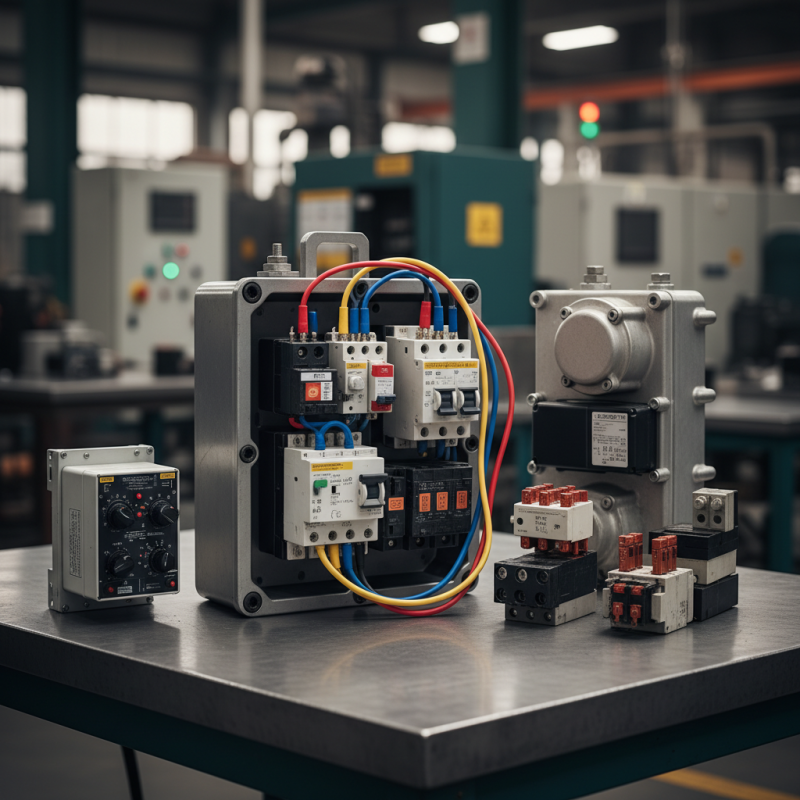

Understanding Different Types of Motor Protection Devices Available in the Market

When selecting motor protection devices, understanding the options is essential. There are various protection devices available, each serving a unique purpose. Overload relays help prevent motors from overheating due to excessive current. According to the US Department of Energy, properly sized overload relays can reduce energy losses by up to 10%. Circuit breakers are another critical component, offering short-circuit protection and preventing equipment damage.

Surge protectors are designed to guard against voltage spikes. They can protect sensitive electronic components in motors. Businesses often overlook these devices, leading to costly repairs. A report from the Institute of Electrical and Electronics Engineers states that up to 30% of industrial equipment damage occurs due to voltage surges.

Further, thermal protection devices monitor motor temperature. If the motor exceeds a preset temperature, these devices automatically shut it down. This can be vital in preventing catastrophic failures. However, many facilities still rely solely on manual checks, exposing them to unanticipated failures. Regular assessments of existing motor protection can reveal whether current systems effectively mitigate risks.

Evaluating the Voltage and Current Ratings for Effective Motor Protection

Selecting the right motor protection for equipment requires careful evaluation of voltage and current ratings. Incorrect ratings can lead to severe equipment failures. According to a recent industry report, nearly 30% of motor failures are linked to improper protection devices. This highlights the critical need for understanding electrical specifications.

Voltage ratings should match the motor's requirements for efficient operation. If the voltage rating is too low, the motor may underperform. Conversely, if it’s too high, it can lead to insulation breakdown. This type of oversight can be costly. Additionally, current ratings must be assessed to prevent overload. Overcurrent can cause overheating, resulting in damage or even fire hazards.

Proper rating selection is not always straightforward. Many users overlook the fine print, which provides vital information. It’s also essential to consider environmental factors. High humidity and extreme temperatures affect the motor’s performance. Yet, many fail to factor these into their decisions. The balance between performance and environment plays a crucial role in achieving reliable motor operation.

Analyzing the Impact of Motor Protection on Equipment Lifespan and Efficiency

Motor protection plays a crucial role in determining the lifespan and efficiency of your equipment. Properly selected motor protection mechanisms can prevent unexpected failures and reduce downtime. When a motor is well-secured against overloads, short circuits, and overheating, it operates at optimal levels. This can significantly increase its service life. Better protection often leads to fewer replacements and repairs, saving costs in the long run.

However, not all protection options are created equal. Choosing the right one requires careful analysis of your equipment’s specific needs. Overprotecting can lead to unnecessary failures too. Devices may trip frequently, disrupting production processes. This creates frustration and potential losses. On the other hand, under-protecting can risk motor damage. Neglecting maintenance and monitoring may lead to catastrophic failures.

The effectiveness of motor protection directly affects energy efficiency. Motors without adequate shields can consume more power when under stress. This inefficiency not only impacts operational costs but also the environment. Striking a balance between over and under protection is crucial. Regular assessments can help identify the best fit for your equipment, ensuring it performs efficiently and lasts longer.

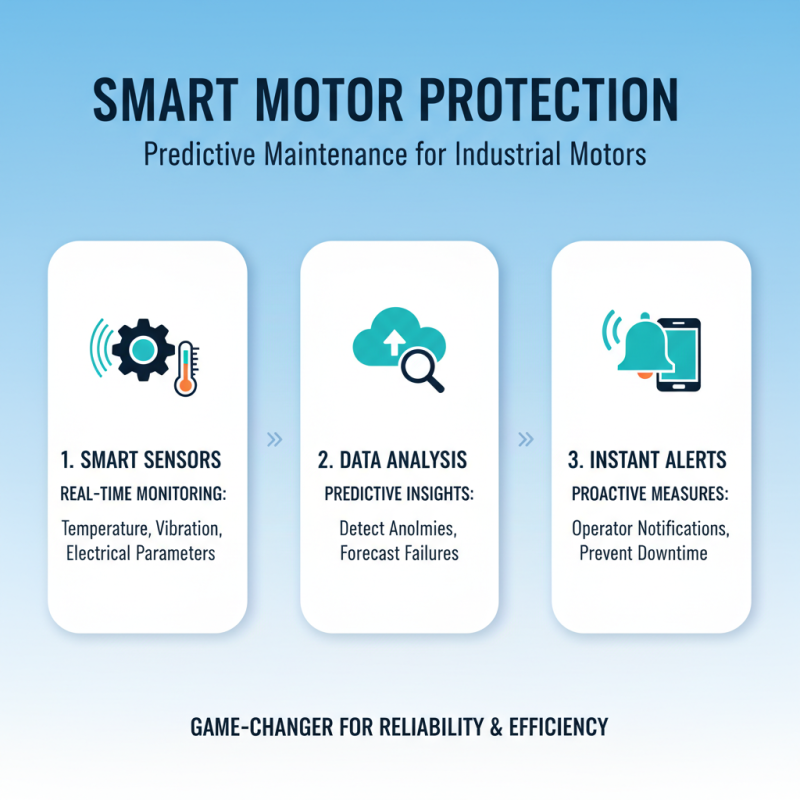

Integrating Smart Technology Solutions in Motor Protection Systems for Optimal Safety

When it comes to motor protection systems, integrating smart technology is a game changer. Smart sensors can monitor temperature, vibration, and electrical parameters in real-time. This data is invaluable for predicting potential failures before they occur. For instance, a small increase in temperature might indicate an issue. High-tech alarms can then alert operators instantly.

Another essential aspect is the usability of these systems. Not all smart solutions are user-friendly. Complex interfaces can confuse operators. Therefore, choosing a system with intuitive design is crucial. Simple dashboards help teams respond quickly to alerts. Consider also how data is collected and analyzed. It must be actionable and clear.

However, integrating technology isn't always seamless. Compatibility with existing systems can be an issue. Some older equipment may struggle with new tech. Also, training staff may take time. A poorly executed implementation can lead to frustration. Reflecting on past failures in integration can lead to better decision-making. It’s vital to strike the right balance between technology and practicality.

Related Posts

-

Exploring the Impact of Motor Protection Technologies at the 138th Canton Fair 2025 in China

-

Ultimate Guide to Understanding Motor Protection Solutions for Industrial Applications

-

How to Choose the Right Motor Protection Relay for Your Application

-

Understanding Challenges Faced with Electric Breaker Switches in Modern Applications

-

Understanding the Importance of Motor Protection Relay in Electrical Safety Systems

-

Top 10 Benefits of Using Soft Starters in Industrial Applications