What is an Air Circuit Breaker and How Does it Work?

In the world of electrical engineering, the air circuit breaker (ACB) is essential for safeguarding electrical circuits. Dr. Emily Carter, an expert in circuit protection, notes, "Air circuit breakers are vital for modern electrical systems." These devices operate by interrupting current flow during overload or short-circuit conditions, thus preventing damage and ensuring safety.

Air circuit breakers utilize air as the medium for arc extinction, which is a unique feature. When the circuit is interrupted, the airflow helps cool the arc, allowing for quick disconnection. This method enhances reliability and minimizes the risk of electrical fires. However, it’s crucial to recognize the limitations of air circuit breakers. They require regular maintenance to function effectively. Neglecting this can lead to unforeseen failures.

Despite their advantages, some may overlook the significance of selecting the right ACB. Proper sizing and specifications are critical. An ill-fitted breaker can result in inefficiencies. Understanding the intricacies of air circuit breakers ensures that they serve their purpose. Further exploration into their design can reveal opportunities for improvement.

Definition of Air Circuit Breaker and Its Purpose

An air circuit breaker (ACB) is a crucial component in electrical systems. It is designed to protect circuits from overloads and short circuits. This device helps in maintaining electrical stability, especially in industrial settings. An ACB can detect faults and disconnect power effectively. It uses air as the medium for arc extinction when heavy current flows are interrupted.

The main purpose of an air circuit breaker is to ensure safety. By interrupting current, it prevents potential hazards like fires and equipment damage. ACBs are also useful for managing energy distribution. They can handle high current ratings and are often found in substations and large facilities. However, improper installation or maintenance can lead to malfunctions. Regular checks are vital to ensuring their reliability.

ACBs come in various types, each serving particular needs. Some may not trip as expected during a fault, raising concerns. This prompts the need for further testing and adjustments. Understanding the operation and limitations of air circuit breakers is essential for effective use. Proper training for operators can improve overall performance and safety in electrical environments.

Air Circuit Breaker Current Ratings

This bar chart represents the current ratings for various sizes of air circuit breakers. The ratings indicate the maximum current that the circuit breaker can handle before tripping.

Components of an Air Circuit Breaker

Air circuit breakers (ACBs) play a crucial role in electrical systems. Their primary function is to protect circuits from overloads and short circuits. The main components of an ACB include the operating mechanism, contacts, and arc extinguishing chamber. These elements work together to ensure safety and reliability in electrical systems.

The operating mechanism is the heart of an ACB. It can be manual or automatic, depending on the design. It triggers the opening of contacts when needed. Contacts, typically made of silver or copper, establish the electrical connection. They undergo wear and tear over time, which can affect performance. Regular inspections are necessary for maintaining their efficiency.

The arc extinguishing chamber is critical during fault conditions. When the circuit breaks, it generates an arc between the contacts. This chamber helps to extinguish the arc quickly and prevents further damage. Studies show that effective arc extinction increases device life and operational safety. However, challenges remain in optimizing these components for varying conditions. Balancing cost and performance is essential for effective ACB design.

Working Principle of Air Circuit Breakers

Air circuit breakers (ACBs) are essential devices in electrical systems. They provide overload and short-circuit protection. Understanding their working principle helps in grasping their importance.

The core function of an ACB is to detect fault conditions. When a fault occurs, the breaker opens automatically. This action disconnects the electrical circuit quickly. There are several components involved in this process. The thermal element responds to excess current. Meanwhile, an electromagnetic element reacts to rapid surges. Together, they ensure timely interruption of the circuit.

ACBs often use air as the medium for quenching arcs. When the contacts open, an arc forms. The air cools and extinguishes this arc, preventing damage. However, maintenance is crucial. Dust can accumulate, affecting performance. Neglecting this can lead to failures. Regular checks are necessary for optimal function. Aim to ensure a consistent and reliable operation.

What is an Air Circuit Breaker and How Does it Work? - Working Principle of Air Circuit Breakers

| Feature | Description |

|---|---|

| Definition | An Air Circuit Breaker (ACB) is an electrical device that breaks the circuit in case of overcurrent or short-circuit conditions. |

| Working Principle | ACBs operate by using air as the medium for interrupting the current flow, which is achieved through the ionization of air under high voltage conditions. |

| Components | Main components include contacts, arc chamber, operating mechanism, and trip unit. |

| Types | Types include plain break, magnetic blowout, and air chute types. |

| Applications | Used in industrial settings to protect large electrical systems from overloads and short circuits. |

| Advantages | Advantages include high breaking capacity, low maintenance, and reliable performance. |

| Disadvantages | Disadvantages can include size, weight, and slower response time compared to other types of circuit breakers. |

Types of Air Circuit Breakers and Their Applications

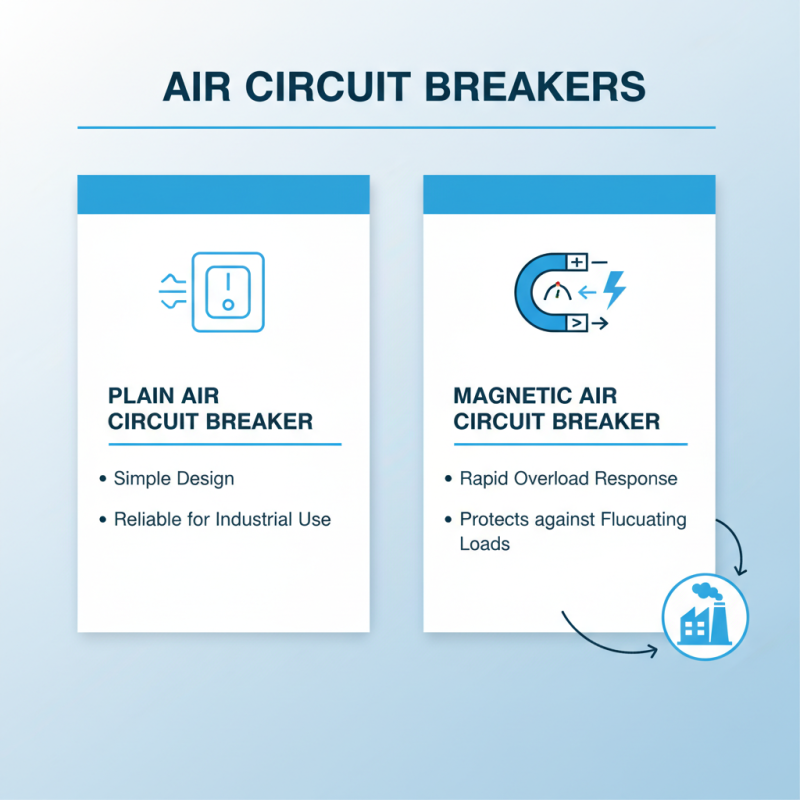

Air circuit breakers (ACBs) come in several types, each suitable for different applications. One common type is the plain air circuit breaker. It is known for its simple design and reliability. This makes it a popular choice in industrial settings. Another type is the magnetic air circuit breaker. Its quick response to overloads protects electrical systems effectively. This feature is crucial in environments with fluctuating loads.

Hydraulic air circuit breakers are designed for more demanding conditions. These breakers use hydraulic systems to trip, providing a higher level of protection. They are particularly used in heavy machinery operations. A variable frequency drive circuit breaker, on the other hand, caters to systems with variable speed applications. It offers precise control, making it ideal for pumps and motors.

Each type has its own strengths and weaknesses. Users sometimes underestimate the importance of selecting the correct type of ACB. For instance, choosing a less responsive breaker in a dynamic environment could lead to failures. Ensuring proper application selection can be challenging but is essential for safety. Failure to do so can result in equipment damage and increased downtime.

Benefits and Limitations of Using Air Circuit Breakers

Air circuit breakers (ACBs) offer several benefits that make them popular in electrical systems. They provide excellent protection against overloads and short circuits. ACBs can interrupt high fault currents effectively. Their design allows for quick disconnection, minimizing potential damage. Moreover, they are capable of handling larger currents. This is ideal for both industrial and commercial settings.

However, ACBs have their limitations. They can be bulky and may require significant space in electrical panels. Installation can be complex, demanding careful planning. Maintenance is another concern; ACBs require regular checks to ensure reliability. Their performance can decline if not properly maintained.

Additionally, they may not be cost-effective for smaller applications. In some cases, the upfront costs can be higher than other options. Users need to weigh these factors carefully when choosing the right solution.

Related Posts

-

A Comprehensive Guide to Understanding Molded Case Circuit Breakers in Industrial Applications

-

Top 10 Benefits of Using Air Circuit Breakers for Safety?

-

7 Essential Tips for Choosing the Right Electric Breaker for Your Needs

-

Ultimate Guide to Choosing the Right Surge Protection Circuit Breaker for Your Needs

-

How to Choose the Right Electric Breaker for Optimal Safety and Efficiency

-

Ultimate Guide to ACB Breaker Selection and Maintenance for Optimal Performance